Instant Connection for Pixel Streaming

— New Feature Automated Setup

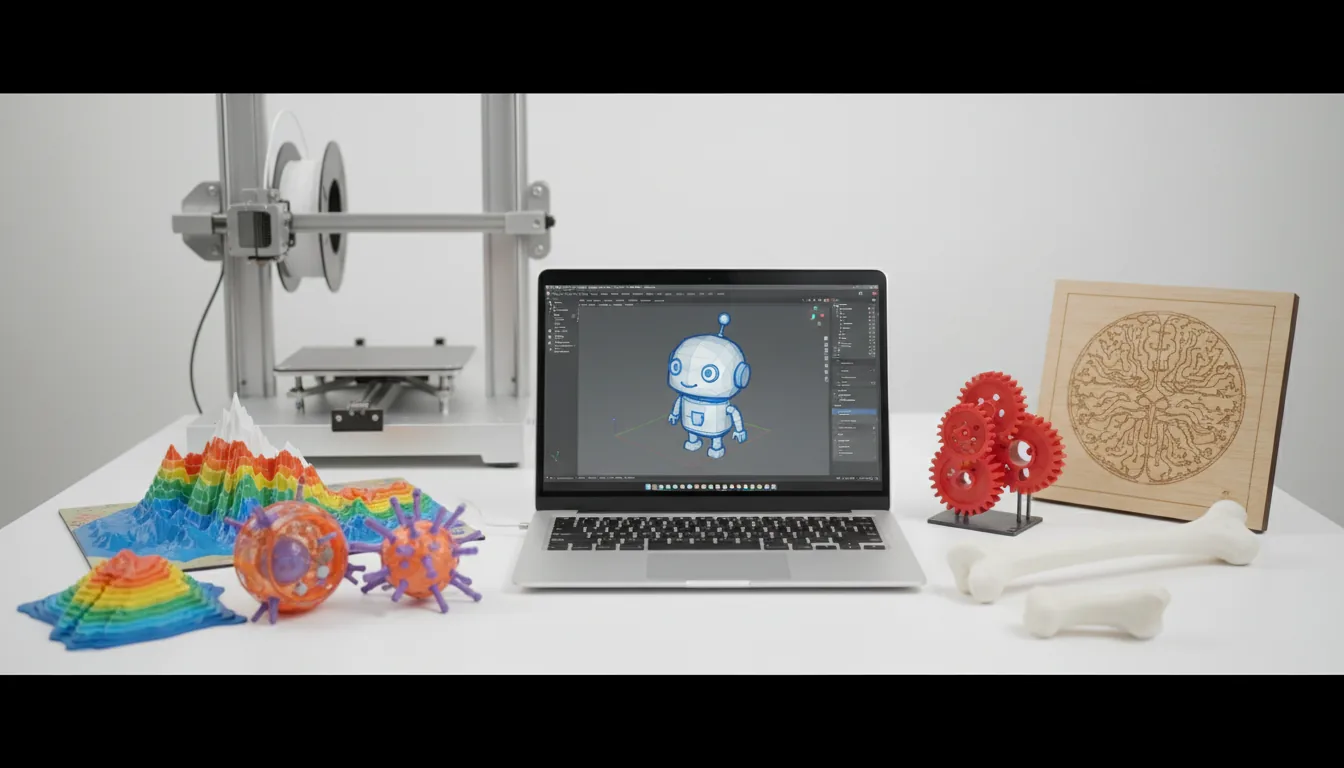

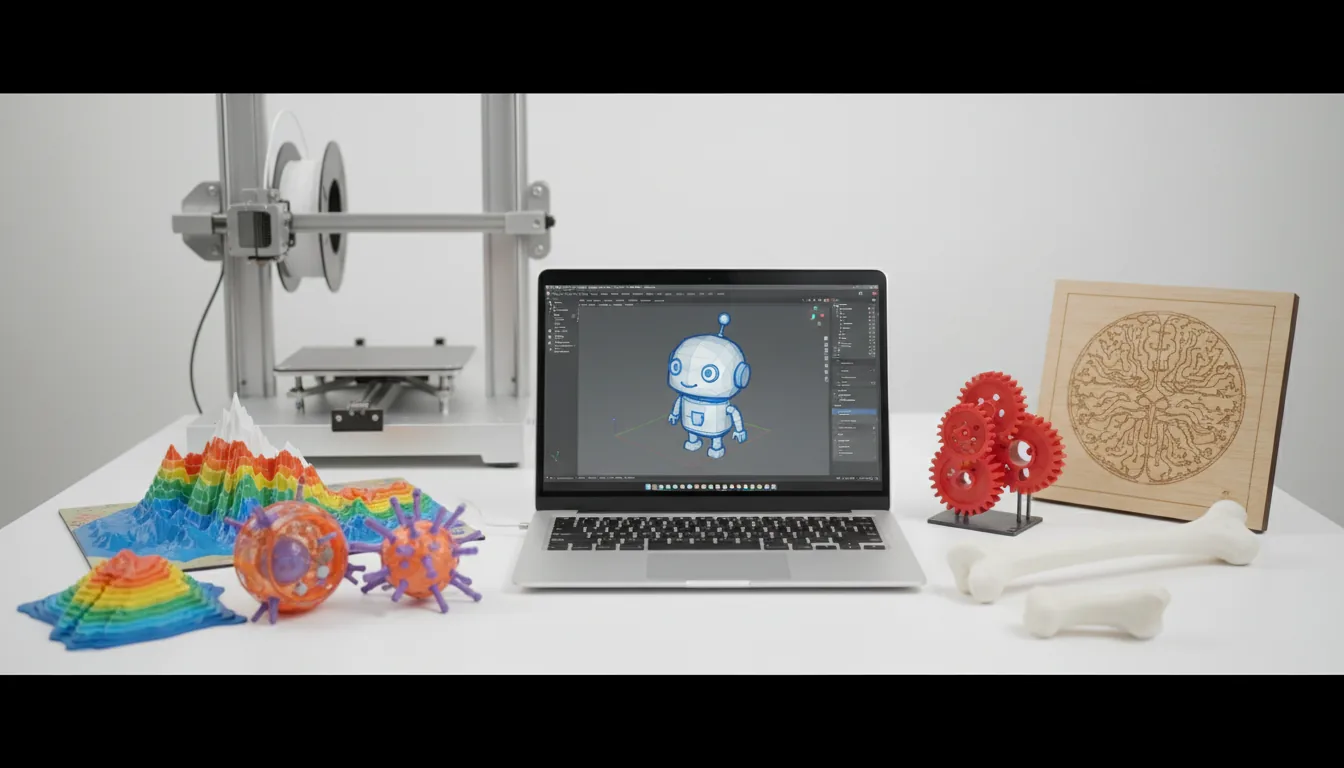

Tips to Improve the Quality of Your 3D Designs

Tips to Improve the Quality of Your 3D Designs

Tips to Improve the Quality of Your 3D Designs

Published on July 29, 2022

Updated on August 13, 2025

Table of Contents

Although it may seem easy at first, 3D printing comes with a fairly high initial learning curve. Enthusiastic intermediate users might get frustrated when they find they’re not producing 3D designs that are at the level they’re happy with.

Just like with any technical process though, 3D print quality can improve with some realistic expectations, some patience, and a whole lot of fine-tuning. If you don’t know where to start though, following our tips on the 4 M’s of 3D printing should help!

Model

Make sure that your digital 3D model and the file settings that come with it are optimized for printing. Most low-quality 3D prints are caused by digital models that just aren’t designed to be 3D prints.

When working with models that are off-balanced or top-heavy, use your slicer program to add sufficient supports. If you’re working on models with fine or delicate details, scale them up so that the details don’t get washed out by your printer’s native resolution. Either that or use a lower layer height to hopefully capture all the tiny curves and valleys in your model.

Try to learn all the ins and outs of your 3D modeling software and slicer so you can use them both to their full potential.

Method

Depending on the complexity of the project, most 3D prints take upwards of hours to complete. Unless you’re dedicated enough to keep an eye on it the whole time, take some measures beforehand to make sure you have a consistently accurate and clean process from start to finish.

Deal with any potential vibrations that could offset the print nozzle and cause ghosting. Another cause of inaccurate prints is a run time that’s too fast for the print - be sure to be patient and not rush your machine’s print settings.

After printing, take the time to sand and polish your finished products. Whether it’s for art or for more utilitarian purposes, you can never go wrong with proper post-processing.

Materials

Generally speaking, there are two types of 3D printers - fused deposition modeling (FDM), which uses extruded thermo-plastic filaments to form an object, and Stereolithography (SLA) printers, an older way of producing 3D prints using lasers and cured liquid resin.

Out of the two, FDM is more commonly used by hobbyists and beginners while SLA is less common but more ideal for certain more detailed prints. Depending on your printer and the type of 3D design you’re trying to make, it’s important that you choose the right filament or resin for you and adjust your printer settings accordingly.

Maintenance

Keep your 3D printer parts and workspace clean, organized, and up to date. Keep track of parts that are worn down by the 3D printing process and those that need to be replaced. The same goes for your digital assets - make sure that the programs you use are updated and stable versions.

Always keep your machine properly calibrated. Temperature is a big factor in FDM 3D printing so make sure your nozzle and bed temperatures are set just right for printing. For SLA printers, the same goes for regulating the temperature of the room you’re printing in as well as making sure no sunlight (which prematurely cures UV resin) leaks in.

Monitoring

Once you’ve mastered the basics, one of the best ways to keep your 3D printing consistent is to actively monitor your prints in real time. Even if you can’t physically sit by the printer for the entire duration, there are plenty of remote monitoring solutions—like camera setups or IoT-enabled printer controls—that let you check progress from your phone or computer.

Catching issues early, such as filament tangles, nozzle clogs, or layer shifts, can save you hours of wasted print time and material. This proactive approach doesn’t just prevent failed prints—it also helps you learn exactly when and why something goes wrong so you can adjust faster next time.

Conclusion

Improving your 3D designs will get frustrating at times but just remember that trial and error is an important part of improvement. If you think you’re doing something wrong, change just a little bit at a time to see if it makes a difference.

Make the changes, reassess the results, and use what you’ve learned to repeat the process and produce better 3D designs. There are no failures in 3D printing, just opportunities for learning. Aim for improvement, not perfection, and eventually, you’ll find yourself making top-quality, high-class 3D designs in no time.

Although it may seem easy at first, 3D printing comes with a fairly high initial learning curve. Enthusiastic intermediate users might get frustrated when they find they’re not producing 3D designs that are at the level they’re happy with.

Just like with any technical process though, 3D print quality can improve with some realistic expectations, some patience, and a whole lot of fine-tuning. If you don’t know where to start though, following our tips on the 4 M’s of 3D printing should help!

Model

Make sure that your digital 3D model and the file settings that come with it are optimized for printing. Most low-quality 3D prints are caused by digital models that just aren’t designed to be 3D prints.

When working with models that are off-balanced or top-heavy, use your slicer program to add sufficient supports. If you’re working on models with fine or delicate details, scale them up so that the details don’t get washed out by your printer’s native resolution. Either that or use a lower layer height to hopefully capture all the tiny curves and valleys in your model.

Try to learn all the ins and outs of your 3D modeling software and slicer so you can use them both to their full potential.

Method

Depending on the complexity of the project, most 3D prints take upwards of hours to complete. Unless you’re dedicated enough to keep an eye on it the whole time, take some measures beforehand to make sure you have a consistently accurate and clean process from start to finish.

Deal with any potential vibrations that could offset the print nozzle and cause ghosting. Another cause of inaccurate prints is a run time that’s too fast for the print - be sure to be patient and not rush your machine’s print settings.

After printing, take the time to sand and polish your finished products. Whether it’s for art or for more utilitarian purposes, you can never go wrong with proper post-processing.

Materials

Generally speaking, there are two types of 3D printers - fused deposition modeling (FDM), which uses extruded thermo-plastic filaments to form an object, and Stereolithography (SLA) printers, an older way of producing 3D prints using lasers and cured liquid resin.

Out of the two, FDM is more commonly used by hobbyists and beginners while SLA is less common but more ideal for certain more detailed prints. Depending on your printer and the type of 3D design you’re trying to make, it’s important that you choose the right filament or resin for you and adjust your printer settings accordingly.

Maintenance

Keep your 3D printer parts and workspace clean, organized, and up to date. Keep track of parts that are worn down by the 3D printing process and those that need to be replaced. The same goes for your digital assets - make sure that the programs you use are updated and stable versions.

Always keep your machine properly calibrated. Temperature is a big factor in FDM 3D printing so make sure your nozzle and bed temperatures are set just right for printing. For SLA printers, the same goes for regulating the temperature of the room you’re printing in as well as making sure no sunlight (which prematurely cures UV resin) leaks in.

Monitoring

Once you’ve mastered the basics, one of the best ways to keep your 3D printing consistent is to actively monitor your prints in real time. Even if you can’t physically sit by the printer for the entire duration, there are plenty of remote monitoring solutions—like camera setups or IoT-enabled printer controls—that let you check progress from your phone or computer.

Catching issues early, such as filament tangles, nozzle clogs, or layer shifts, can save you hours of wasted print time and material. This proactive approach doesn’t just prevent failed prints—it also helps you learn exactly when and why something goes wrong so you can adjust faster next time.

Conclusion

Improving your 3D designs will get frustrating at times but just remember that trial and error is an important part of improvement. If you think you’re doing something wrong, change just a little bit at a time to see if it makes a difference.

Make the changes, reassess the results, and use what you’ve learned to repeat the process and produce better 3D designs. There are no failures in 3D printing, just opportunities for learning. Aim for improvement, not perfection, and eventually, you’ll find yourself making top-quality, high-class 3D designs in no time.

Get Beyond Your Computer Performance

Run applications on your cloud computer with the latest generation hardware. No more crashes or lags.

Trial includes 1 hour usage + 7 days of storage.

Get Beyond Your Computer Performance

Run applications on your cloud computer with the latest generation hardware. No more crashes or lags.

Trial includes 1 hour usage + 7 days of storage.

Ready to focus on your creativity?

Vagon gives you the ability to create & render projects, collaborate, and stream applications with the power of the best hardware.

Vagon Blog

Run heavy applications on any device with

your personal computer on the cloud.

San Francisco, California

Solutions

Vagon Teams

Vagon Streams

Use Cases

Resources

Vagon Blog

Best VMware Horizon Alternatives for VDI Teams in 2026

Top Citrix Alternatives in 2026

Top Azure Virtual Desktop Alternatives in 2026

Best Laptops of 2026: What Actually Matters

Best 3D Printers in 2026: Honest Picks, Real Use Cases

Best AI Productivity Tools in 2026: Build a Smarter Workflow

Best AI Presentation Tools in 2026: What Actually Works

Best Video Editing Software in 2026: Premiere Pro, DaVinci Resolve & More

The Best AI Video Generators in 2026: Tested Tools, Real Results

Vagon Blog

Run heavy applications on any device with

your personal computer on the cloud.

San Francisco, California

Solutions

Vagon Teams

Vagon Streams

Use Cases

Resources

Vagon Blog

Best VMware Horizon Alternatives for VDI Teams in 2026

Top Citrix Alternatives in 2026

Top Azure Virtual Desktop Alternatives in 2026

Best Laptops of 2026: What Actually Matters

Best 3D Printers in 2026: Honest Picks, Real Use Cases

Best AI Productivity Tools in 2026: Build a Smarter Workflow

Best AI Presentation Tools in 2026: What Actually Works

Best Video Editing Software in 2026: Premiere Pro, DaVinci Resolve & More

The Best AI Video Generators in 2026: Tested Tools, Real Results

Vagon Blog

Run heavy applications on any device with

your personal computer on the cloud.

San Francisco, California

Solutions

Vagon Teams

Vagon Streams

Use Cases

Resources

Vagon Blog

Best VMware Horizon Alternatives for VDI Teams in 2026

Top Citrix Alternatives in 2026

Top Azure Virtual Desktop Alternatives in 2026

Best Laptops of 2026: What Actually Matters

Best 3D Printers in 2026: Honest Picks, Real Use Cases

Best AI Productivity Tools in 2026: Build a Smarter Workflow

Best AI Presentation Tools in 2026: What Actually Works

Best Video Editing Software in 2026: Premiere Pro, DaVinci Resolve & More

The Best AI Video Generators in 2026: Tested Tools, Real Results

Vagon Blog

Run heavy applications on any device with

your personal computer on the cloud.

San Francisco, California

Solutions

Vagon Teams

Vagon Streams

Use Cases

Resources

Vagon Blog